Lean provides organizations in many industries a set of valuable tools for eliminating wastes in…

In process improvement circles, you will hear the words Lean and Six Sigma being debated. Both of these terms offer organizations a method for eliminating waste. They do this by finding the root cause of the waste and eliminating it, but the biggest difference is how they approach this.

What is Lean?

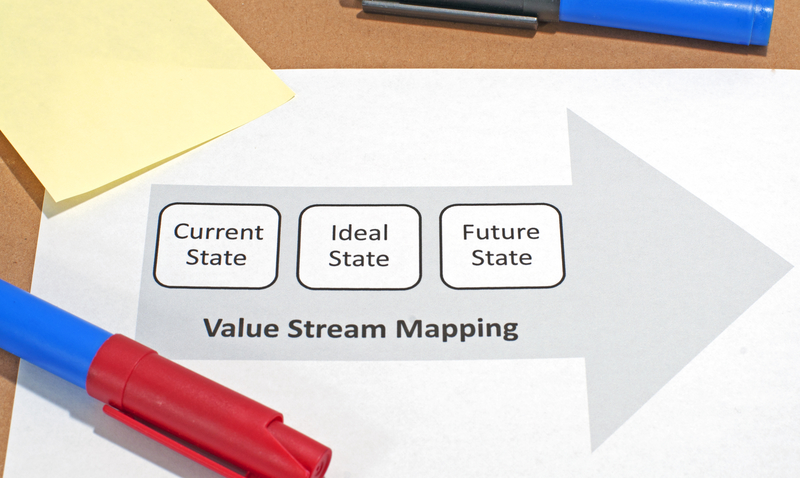

Lean examines organizational processes, whether in manufacturing or healthcare, and looks for ways to streamline them. The processes are broken down step by step to find which ones add value which ones don’t. Any step that doesn’t add value is considered to be waste.

How do we determine whether something has value in Lean? We ask ourselves if it is something that our target customers would purchase. If it is not something the customer would buy, it is eliminated from the process.

What we are left with is a process that is streamlined, efficient and extremely valuable to the customer.

What is Six Sigma?

Six Sigma looks at waste a little differently. It is about improving processes to eliminate the occurrence of defects in a process.

Originally, Six Sigma was intended to only be used in the manufacturing industry. However, managers saw that Six Sigma could be applied to almost any industry. It doesn’t matter whether it is in human resources or the hospitality industry.

Jump forward to modern times, organizations are using Six Sigma to drive measurable results in all areas. It has proven to be so successful that it is now an integral part of organizational leadership.

What’s the Difference?

As you can see, Lean and Six Sigma are quite different. In Lean, waste is the result of additional steps in the process that add no value for the customers. In Six Sigma, waste is the result of variation, which leads to results that differ from the expectations of the customer (defects).

Comments (0)