Giving customers what they need (value) by streamlining organizational processes and creating standardized workflows that…

Lean provides organizations in many industries a set of valuable tools for eliminating wastes in processes. One of them is value stream mapping. Keep reading to find out what it is and why it is important for organizations that want to eliminate waste.

What is Value Stream Mapping (VSM)?

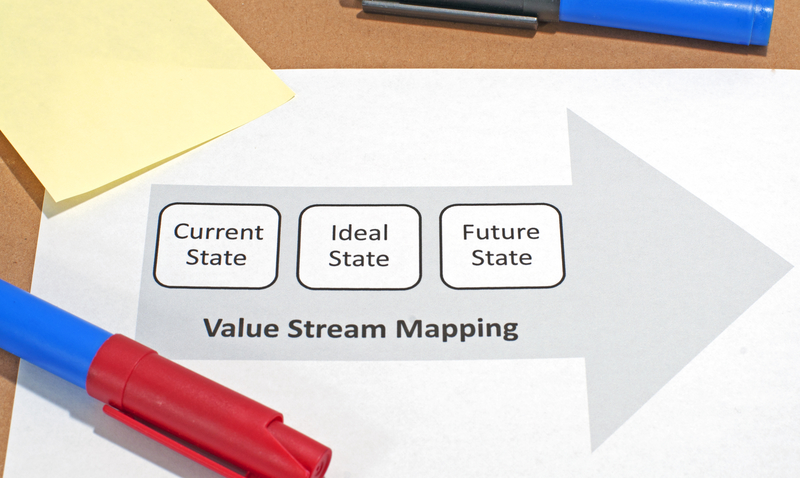

VSM is a method for drawing a diagram, usually a flowchart, that analyzes the steps of a process and outlines how they can be improved. It is an essential tool for any organization that is serious about Lean. The steps where value passes through, from the beginning to the point where the customers get the value, are reviewed and each one is clearly mapped from one to the next, creating a visually coherent flow. The diagram itself consists of symbols that denote activities and the flow of information.

Process improvement teams use these diagrams to find out which activities are contributing value and which ones aren’t. The non-value-adding activities are considered waste and removed from the process.

Why Is Value Stream Mapping Important?

Although VSM is a tool mostly used in manufacturing, that is not the only industry that can benefit from it. It can work anywhere there is a process. Essentially, an organization can analyze a process and see which steps are value-added and which ones are not, based on what its customers perceive as value. This means it keeps the organization more focused on what matters to the customers, making sure each product and service they offer is valuable. Not only does this raise the bottom line due to more sales, but it also means the organization becomes more competitive.

If an organization is in a highly-competitive environment, it can use a value stream map to effectively deliver value to its customers. And the VSM should be constantly re-evaluated to ensure that continuous improvement is established, and the steps in the processes keep getting improved indefinitely.

Apart from that, a value stream map can be used to enhance collaboration and communication within the organization. It can even be used as a tool to drive a change in organizational culture. And, being a visualization tool, VSM gives managers the ability to see exactly what is causing waste in the process. This allows them to visualize the steps that can take the process from the current state to the ideal state by drawing another diagram that represents the desired future state.

Although eliminating waste is at its core, there is no reason why value cannot also be added by way of VSM. Steps that add value – albeit at a lower cost – can be added to make the final product or service much more valuable to the customers. This means customers will be more willing to part with their money.

Conclusion

Value stream mapping is but one of many techniques that organizations can use to eliminate waste. It is an effective means to an end in this regard. When all non-value-added steps are removed from a process, the customers get more value, and the organization cuts costs and maximizes profits.

This Post Has 0 Comments