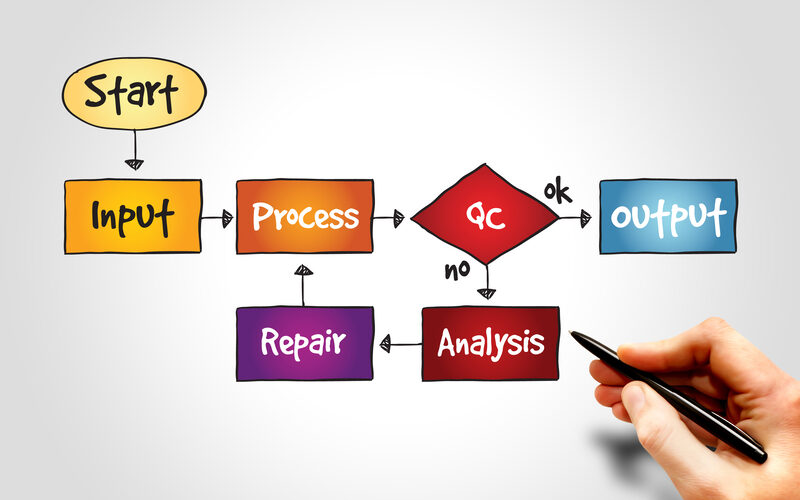

There is something wrong with your process: it keeps failing and you don’t know why.…

One of the most common discussions in business or quality improvement operations is the practice of Six Sigma. To the uninitiated, it sounds exceptionally complicated to understand and implement. It seems even more complicated when trying to understand the roles within a Six Sigma practice. White Belt, Yellow Belt, Green Belt, Black Belt, Master Black Belt … is it a martial arts studio or a business practice? To get some clarity on this is to understand the basic role of Six Sigma. It is defined as terminology associated with statistical modeling of manufacturing processes. The maturity of a manufacturing process can be described by a sigma rating, indicating its yield or the percentage of defect-free products it creates. A Six Sigma process is one in which 99.99966% of all opportunities to produce some feature of a part are statistically expected to be free of defects (3.4 defective features per million opportunities). Within than concept, Six Sigma professionals are just like any other business professionals. Their practice is broken down into a professional skill set ladder. Each skill set level is identified by a ‘belt’ designation. Those designations identify skills, ability and development with the practice of Six Sigma.

The Role of a Green Belt

The Green Belt certification is in the middle of the career ladder of Six Sigma. It is the mid-level workhorse of the practice. A Green Belt brings to the table a deep understanding of the practice, its tools and the application of the professional standards. They spend about half of their work requirements on Six Sigma related activities. The Green Belt functions in support of or under the supervision of a Black Belt. They analyze and solve quality problems and are involved in quality improvement projects.

This Post Has 0 Comments