Lean provides organizations in many industries a set of valuable tools for eliminating wastes in…

The influential work of Joseph Juran, Juran On Quality By Design: New Steps For Planning On Quality Into Goods and Services, makes the case that quality cannot be ‘inspected-in’, but rather ‘built-in’ to have long-term success. This exhaustive work indicates that the majority of service or product failures are the result of poor design.

Pharmaceutical Quality is Built Through QbD

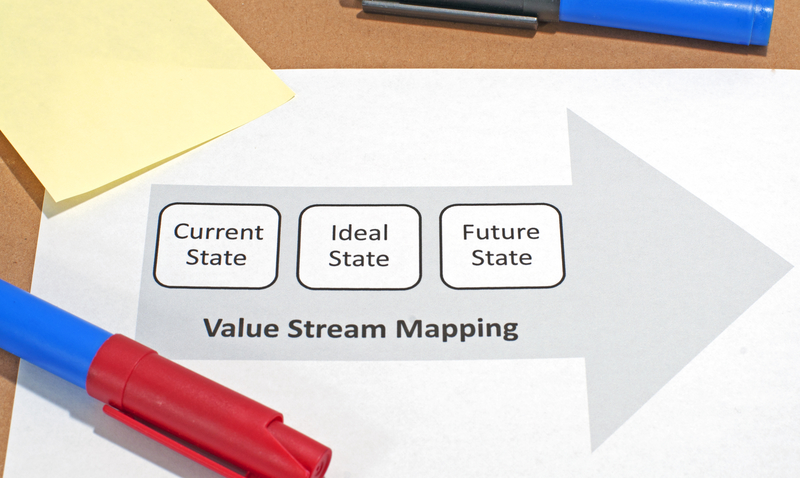

Pharmaceutical QbD is best defined as a systematic approach to development. It begins with defined objectives, which emphasizes process understanding and process control. This approach is based on quality risk management and science. The QbD process is emerging as an effective tool to enhance and support pharmaceutical practices.

Previously, quality was determined almost entirely by post-process inspection, with virtually no foundation to build upon for corrective actions or continuous improvement. This led to major global regulatory authorities for pharmaceuticals driving QbD initiatives over the last ten years that have become initiatives within the industry itself. QbD practice has increasingly become best practice within many pharmaceutical companies. The goals of pharmaceutical QbD may include the following:

- To achieve meaningful product quality specifications that are based on clinical performance

- To increase process capability and reduce product variability and defects by enhancing product and process design, understanding, and control

- To increase product development and manufacturing efficiencies

- To enhance root cause analysis and post approval change management

Under QbD, these goals can often be achieved by linking product quality to the desired clinical performance, and then designing a robust formulation and manufacturing process to consistently deliver the desired product quality.

Enhance Your Skills Through Training

The goals of implementing pharmaceutical QbD are to reduce product variability and defects, thereby enhancing product development and manufacturing efficiencies and post-approval change management. It is achieved by designing a robust formulation and manufacturing process and establishing clinically relevant specifications.

To achieve the best results through this practice, a Lean Six Sigma professional must have a thorough understanding and skill of the tool. Earn your skills with a trusted provider of comprehensive Lean Six Sigma training. Learn more about Pharmaceutical QbD at 6sigma.us.

Comments (0)